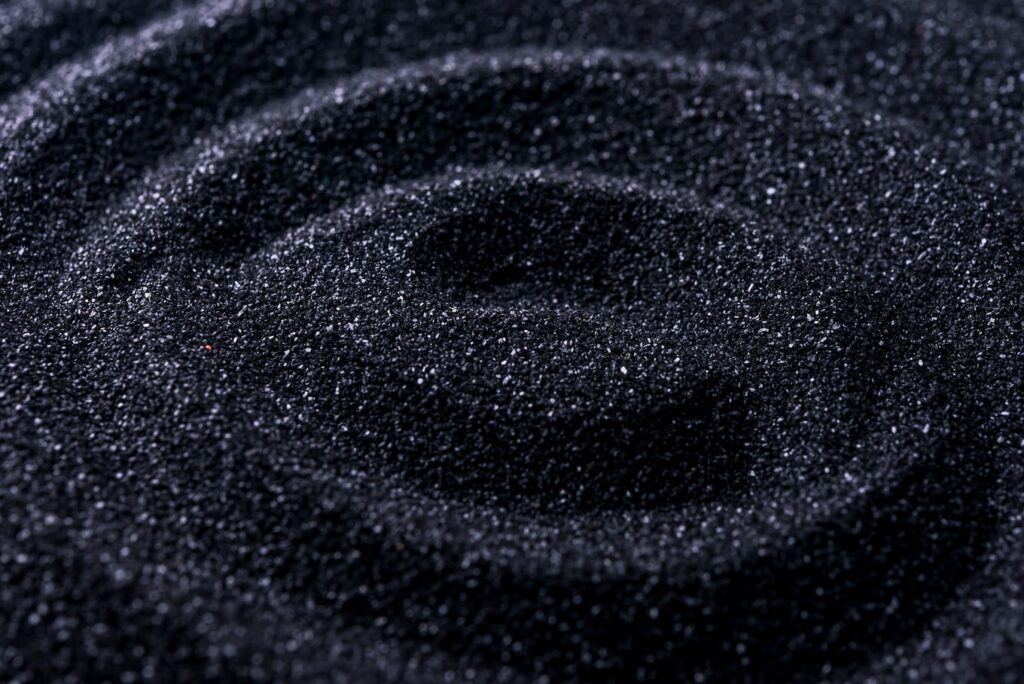

Various Slag Grits

Product

Diverse Slag Grit Solutions

Various Slag Grit, derived from granulated slag produced during metal melting processes, is commonly used in surface blast-cleaning procedures

Abrasive blasting is a method used to cleanse and refine the surfaces of metals, stones, concrete, and diverse materials. A stream of abrasive particles, known as grit, is propelled toward the workpiece during this process. Grit, as a blasting medium, is useful in safeguarding against corrosion and purifying surfaces of various objects such as metal, wood, and plastic, which often bear contamination from corrosion, pigments, and coatings. Leveraging their exceptional abrasive attributes and kinetic energy, various grits emerge as premium materials, effectively employed in anti-corrosion endeavors across a spectrum of applications including steel structures, machinery, and marine vessels

Chemical:

Structure

| SL# | Name | Result % |

| 1 | Fe2O3 | 47-48,6 |

| 2 | FeO | 40-42 |

| 3 | Fe | 33-34 |

| 4 | SiO2 | 34-36 |

| 5 | Al2O3 | 4 – 4,5 |

| 6 | CaO | 8,45 |

| 7 | MgO | 2-2,2 |

| 8 | K2O | 0,5 |

| 9 | Na2O | 0,19 |

| 10 | TiO2 | 0,8 |

| 11 | Cu | 0,2-0,24 |

| 12 | Pb | < 0,1 |

| 13 | Zn | 0.6-0.8 |

| 14 | S | 1-1,4 |

| 15 | As | <0,0010 |

| 16 | Cd | <0,0015 |

| 17 | Ni | <0,0030 |

| 18 | Cr | 0,06-0,07 |

| 19 | Free Silica | <1% |

Material:

Characteristics

| SL# | Parameters | Analytic method | Result |

| 1 | Grain shape | – | Sharp & angular |

| 2 | Bulk Density (kg/dm3) | – | 3,37 |

| 3 | Moh’s Hardness | – | 7,5 |

| 4 | Moisture % | PHY08D | 0,099 |

| 5 | Colour | – | Brownish Black |

| 6 | Water- Soulible Chlorides % | CLA04E | <0,005 |

Applications: Used as blast cleaning abrasive for all applications fields in conventional corrosion protection on almost all surfaces. Suitable for SA-3, SA-2% and SA-2.

Properties: Vitreous amorphous slag. Absorbs no water. Therefore, the single abrasive particle is not broken up and retains its extreme hardness and tenacity which is the case for all particle sizes. Dust reduced. All constituents are present in oxidized form, predominantly as bonded silicate

Grit Traits Overview

- Hardness: 7.5 on Moh's Scale

- Color: Black

- Shape: Irregular prismatic, abundant sharp edges for enhanced abrasiveness and kinetic energy generated by weight and speed in airstream

- Compatibility: Applicable for all blasting tasks with standard equipment

- Size: 0,2 – 2,8mm

Images: